Portable Inclined Screens

The screening process is just as important as the crushing itself. Screens are the heart of every rock processing plant. They are used to classify materials both in different stages of the crushing process and in final product separation.

Endurance, Capacity And Efficiency

Temporary aggregate production is very common for short-term projects like road and dam construction. Since most of the time the equipment is moved out of the temporary quarry, disassembly, transportation and installation expenses add extra costs that can be just as significant as the start-up investment itself. In such cases, despite higher initial investment costs, mobile crushing and screening solutions are better options than stationary ones because of the time-saving disassembly, transportation and installation advantages they provide.

EASY MAINTENANCE THANKS TO OUR MOVABLE FRONT CHUTE WITH SLIDER

Screen mesh is one of the most frequently replaced spare parts on inclined screens. To simplify the maintenance process and reduce downtime, we designed front chutes with sliders for inclined screens bigger than 8 m² so the front chute can be moved without using any lifting equipment. This provides easy access to the screen for maintenance in just a few minutes.

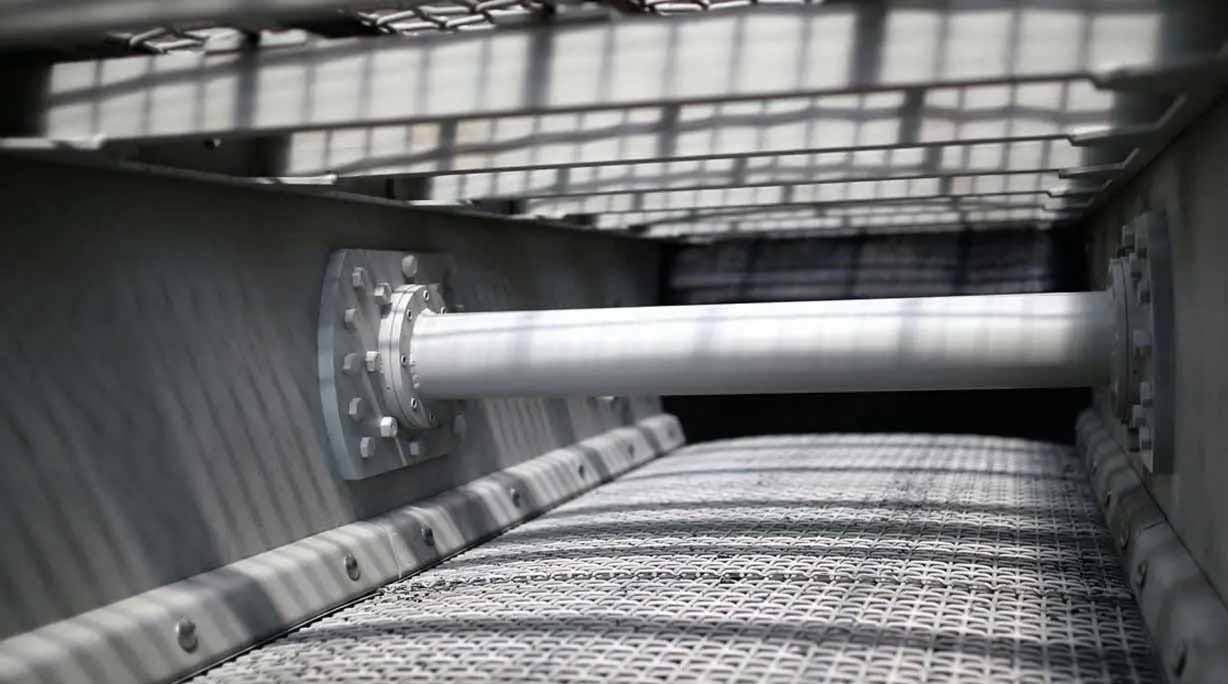

MODULAR-TYPE DRIVE SYSTEM

AGGRETEK inclined screens are equipped with a modular-type drive system for easy servicing. The two-piece drive-shaft system can be detached easily one by one, reducing servicing duration. Additionally, the cardan shaft connecting the modular shafts is more advantageous than traditional heavier and single-piece shafts in terms of easy maintenance.

Wire Cloth Stretching System

Screen meshes are fastened to the screen body by means of screen clamps and sheet bars, after being well stretched at the edges by the tension sheet. Thus, any slackening of the screen meshes during the screening process is prevented.

STANDARD

- Rollaway Chutes

- Blending Chutes

- Switch Gear

- Safety Railings and Ladders (where applicable)

- Manual Jacks

- 1/4″ AR400 Chute Liners

- 330 piw 3/16 x 1/16 3 ply Belting

OPTIONAL

- Static Chutes

- Cross Conveyors

- Spare Tire

- Hyrdrualic “Run On” Jacks

- All Media Options Available

- 1/2′ AR400 Chute Liners

- Other Belt Grads Available Upon Request

- Additional Motor Starters for Conveyors

IMPERIAL

Dimensions

in feet

ASI4132

ASI5132

ASI5162

ASI6162

ASI6202

ASI7202

ASI8202

Number of Decks

ASI4132

ASI5132

ASI5162

ASI6162

ASI6202

ASI7202

ASI8202

Power

HP

ASI4132

ASI5132

ASI5162

ASI6162

ASI6202

ASI7202

ASI8202

METRIC

Dimensions

mm

ASI4132

ASI5132

ASI5162

ASI6162

ASI6202

ASI7202

ASI8202

Number of Decks

ASI4132

ASI5132

ASI5162

ASI6162

ASI6202

ASI7202

ASI8202

Power

kW

ASI4132

ASI5132

ASI5162

ASI6162

ASI6202

ASI7202

ASI8202

High Quality Screen Body Steel Plates

Every inclined screen is made of high-tensile heat-treated side plates that are resistant to vibration, allowing our customers to use them long-term with the same durability as during first use.

Self Tensioned Motorbase

AGGRETEK inclined screens, a self-tentioned motorbase is a standard feature to protect both the electric motor and drive belts against teneion caused by vibrations, meaning less maintenance duratio and lower costs for our customers.

Huck-Bolted

Side plates are made from high quality steel and laser cut holes. Frames are huck-bolted to the side plates insuring structural integrity and eliminates stress fatigue in the screen body.

Motor Base

The motor base coupled with the belt tensioning system enables a practical motor assembly and V belt – pulley replacement, and provides energy efficiency by keeping the belt tention at the desired level. In addition, by providing a bolted connection between the motor frame and the main frame, cracks and fatigue isses associated with welding are avoided.

CORPORATE HEADQUARTERS

150 Isidor Ct. Suite 103

Sparks, Nevada 89441

USA

SALES

Sparks, NV

+1 775-686-6900

DISTRIBUTION CENTER

Sparks, NV

ENGINEERING DIVISION

Maddison, WI

DEALER RELATIONS

Seattle, WA

SERVICE DIVISION

Billings, MT

SALES DEPARTMENT

Office: 775-686-6900

sales@aggretek.com

LOGISTICS

logistics@aggretek.com

Office: 775-686-6900 ext. 125

PARTS DEPARTMENT

parts@aggretek.com

Office: 775-686-6900 ext. 128

SERVICE DEPARTMENT

service@aggretek.com

Office: 775-686-6900

DEALER DEVELOPMENT

dealers@aggretek.com

Office: +1 775-686-6900