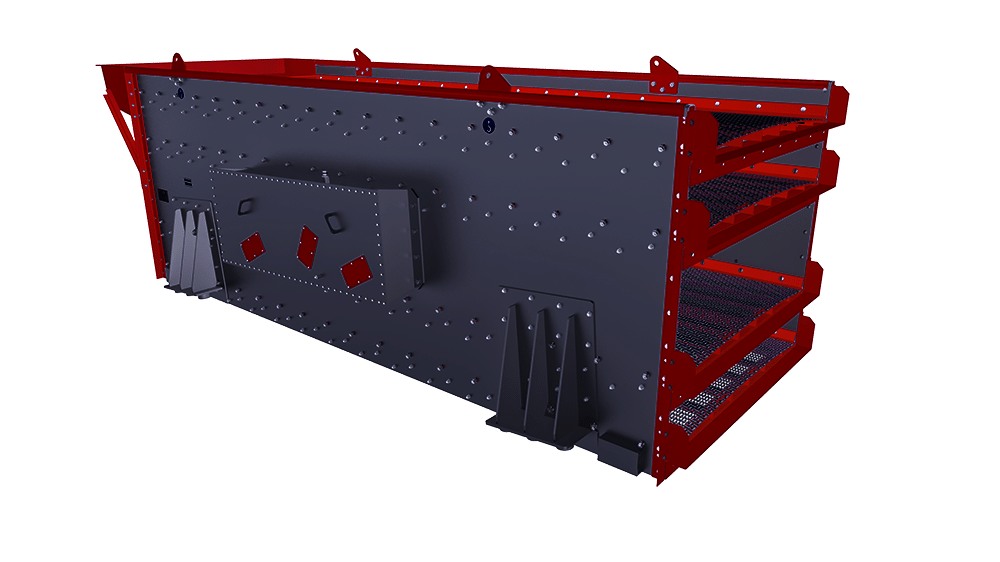

Horizontal Screens

Nowadays, customers are requiring tighter specifications for products for precisely shaped aggregate or closely-sized stone. As a result, tighter control over the process is of utmost importance and the most effective point to do that is at screening. For that critical step you can trust AGGRETEK Horizontal Screens.

Oval Stroke Geared To Productivity

Temporary aggregate production is very common for short-term projects like road and dam construction. Since most of the time the equipment is moved out of the temporary quarry, disassembly, transportation and installation expenses add extra costs that can be just as significant as the start-up investment itself. In such cases, despite higher initial investment costs, mobile crushing and screening solutions are better options than stationary ones because of the time-saving disassembly, transportation and installation advantages they provide.

Adjusting the stroke angle has been found to be the most influential in optimizing the screen efficiency. Higher stroke angles increase the number of chances the material has to pass through the openings and also increases the impact to shake fines loose. Lowering the stroke angle increases the travel rate for heavy screening or scalping operations. Higher speed is sometimes desired for scalping duty.

Wire Cloth Stretching System

Screen meshes are fastened to the screen body by means of screen clamps and sheet bars, after being well stretched at the edges by the tension sheet. Thus, any slackening of the screen meshes during the screening process is prevented.

Other Benefits

– Lower operation noise

– Increase safety for operators

– Smoother shut down of the screen

Bearing and Lubrication

Self aligning taper roller bearings are used to withstand the high thrust and radial loads under which the drive shafts of the triple drive system operate. The roller bearing lubrication is carried out by oil lubrication in an oil bath, which reduces operating temperature for increased bearing life and results in low maintenance.

Other benefits include:

- Less horsepower required

- Smooth running-eliminates jerking action of straight stroke screens

- Adjustable angle and length of stroke

- High capacity and efficiency

- High G force action for better material stratification, reduced plugging and greater range of screenable material

Mounting Arrangement

Coiled springs or with reinforced rubber springs depending on the application. Coiled spring is used when there is no threat of corrosion or abrasion, when there are plenty of opportunities for maintenance and spring replacement, and when loss of time due to problems caused by spring fracture is not an issue. Rubber spring should be used when there is a risk of corrosion or abrasion, when there are limited opportunities for maintenance and spring replacement, and where any halt in production will result in significant costs.

STANDARD

- Rollaway Chutes

- Blending Chutes

- Switch Gear

- Safety Railings and Ladders (where applicable)

- Manual Jacks

- 1/4″ AR400 Chute Liners

- 330 piw 3/16 x 1/16 3 ply Belting

OPTIONAL

- Static Chutes

- Cross Conveyors

- Spare Tire

- Hyrdrualic “Run On” Jacks

- All Media Options Available

- 1/2′ AR400 Chute Liners

- Other Belt Grads Available Upon Request

- Additional Motor Starters for Conveyors

Models and Specifications

IMPERIAL

Size

feet

ASH6162

ASH6163

ASH6202

ASH6203

ASH7162

ASH7163

ASH7202

ASH7203

ASH8162

ASH8163

ASH8202

ASH8203

# of Decks

qty

ASH6162

ASH6163

ASH6202

ASH6203

ASH7162

ASH7163

ASH7202

ASH7203

ASH8162

ASH8163

ASH8202

ASH8203

Drive

HP

ASH6162

ASH6163

ASH6202

ASH6203

ASH7162

ASH7163

ASH7202

ASH7203

ASH8162

ASH8163

ASH8202

ASH8203

Speed

rpm

ASH6162

ASH6163

ASH6202

ASH6203

ASH7162

ASH7163

ASH7202

ASH7203

ASH8162

ASH8163

ASH8202

ASH8203

Weight

lbs

ASH6162

ASH6163

ASH6202

ASH6203

ASH7162

ASH7163

ASH7202

ASH7203

ASH8162

ASH8163

ASH8202

ASH8203

METRIC

Size

mm

ASH6162

ASH6163

ASH6202

ASH6203

ASH7162

ASH7163

ASH7202

ASH7203

ASH8162

ASH8163

ASH8202

ASH8203

# of Decks

qty

ASH6162

ASH6163

ASH6202

ASH6203

ASH7162

ASH7163

ASH7202

ASH7203

ASH8162

ASH8163

ASH8202

ASH8203

Drive

kW

ASH6162

ASH6163

ASH6202

ASH6203

ASH7162

ASH7163

ASH7202

ASH7203

ASH8162

ASH8163

ASH8202

ASH8203

Speed

rpm

ASH6162

ASH6163

ASH6202

ASH6203

ASH7162

ASH7163

ASH7202

ASH7203

ASH8162

ASH8163

ASH8202

ASH8203

Weight

kg

ASH6162

ASH6163

ASH6202

ASH6203

ASH7162

ASH7163

ASH7202

ASH7203

ASH8162

ASH8163

ASH8202

ASH8203

Full Length Spring Support

Spring supports capture all decks for added regidity and stability. This improves resistance to side plate cracking. Fully broke non-welded huck-bolted standard. Option of marsh-mellow coil springs.

High Strength Screen Body

The body of the screen is extremely strong supporting the stresses required by the high power mechanism. This rigidity is provided by frames made from beam sections with stiffeners positioned in critical areas.

Huck-Bolted

Side plates are made from high quality steel and laser cut holes. Frames are huck-bolted to the side plates insuring structural integrity and eliminates stress fatigue in the screen body.

Motor Base

The motor base coupled with the belt tensioning system enables a practical motor assembly and V belt – pulley replacement, and provides energy efficiency by keeping the belt tention at the desired level. In addition, by providing a bolted connection between the motor frame and the main frame, cracks and fatigue isses associated with welding are avoided.

CORPORATE HEADQUARTERS

150 Isidor Ct. Suite 103

Sparks, Nevada 89441

USA

SALES

Sparks, NV

+1 775-686-6900

DISTRIBUTION CENTER

Sparks, NV

ENGINEERING DIVISION

Maddison, WI

DEALER RELATIONS

Seattle, WA

SERVICE DIVISION

Billings, MT

SALES DEPARTMENT

Office: 775-686-6900

sales@aggretek.com

LOGISTICS

logistics@aggretek.com

Office: 775-686-6900 ext. 125

PARTS DEPARTMENT

parts@aggretek.com

Office: 775-686-6900 ext. 128

SERVICE DEPARTMENT

service@aggretek.com

Office: 775-686-6900

DEALER DEVELOPMENT

dealers@aggretek.com

Office: +1 775-686-6900