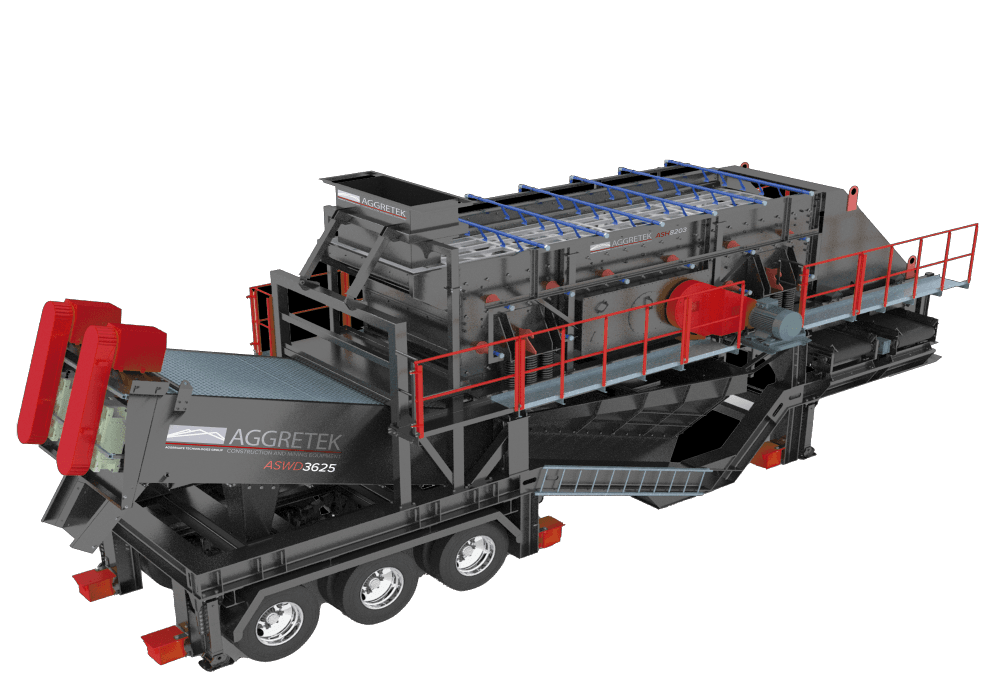

Portable Wash Plant

AGGRETEK Portable Wash Plants are in a category all on its own. Designed from the ground up, you won’t find the features and standard equipment on any competitors machines.

The Fine Material Washer of the Portable Wash Plant offers the largest overflow pool area in its range. This means more valuable fines will be retained in your product while getting rid of more dirt. AGGRETEK Portable Wash Plant is an exceptional profit house for contractor and rental business. Plant loses no time between sites and heavy duty design requires minimal maintenance.

Maximum Efficiency From Your Washing Plant

Temporary aggregate production is very common for short-term projects like road and dam construction. Since most of the time the equipment is moved out of the temporary quarry, disassembly, transportation and installation expenses add extra costs that can be just as significant as the start-up investment itself. In such cases, despite higher initial investment costs, mobile crushing and screening solutions are better options than stationary ones because of the time-saving disassembly, transportation and installation advantages they provide.

AGGRETEK Portable Wash Plant quickly moves to next site to continue working.

AGGRETEK Portable Wash Plant is an exceptional profit house for contractor and rental business.

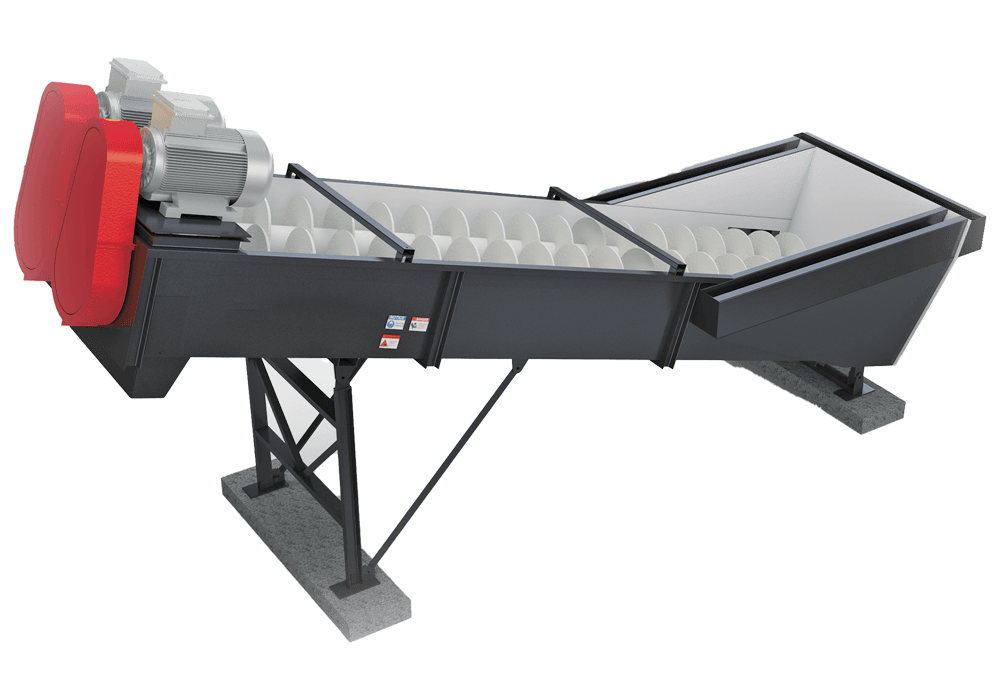

NEXUS Series Fine Material Washer

Wheeled Portable Wash Plant

ASH6203 ASWD3625

OVERALL LENGTH 46 FT 3/4 IN

GROSS WEIGHT 94,000 LBS

TRAVEL WIDTH 10 FT 3 1/2 IN

TRAVEL HEIGHT 14 FT 7-1/4 IN

SPECS

- 1 off ASH6203 Horizontal Screen – True Triple Shaft

- 1 off ASWD3625 Double Fine Material Washer

- 2 off front side discharge conveyors

- Paint is base coat epoxy and top coat urethane machines and chassis

ELECTRICAL

- MCC Panel Pre-Wired •T-stand for Control Panel with tether cable

- Schneider Group Electrical standard

Also available configured with twin 44″ Fine Material Washer ASWD4432

REDLINE Series Horizontal Screen

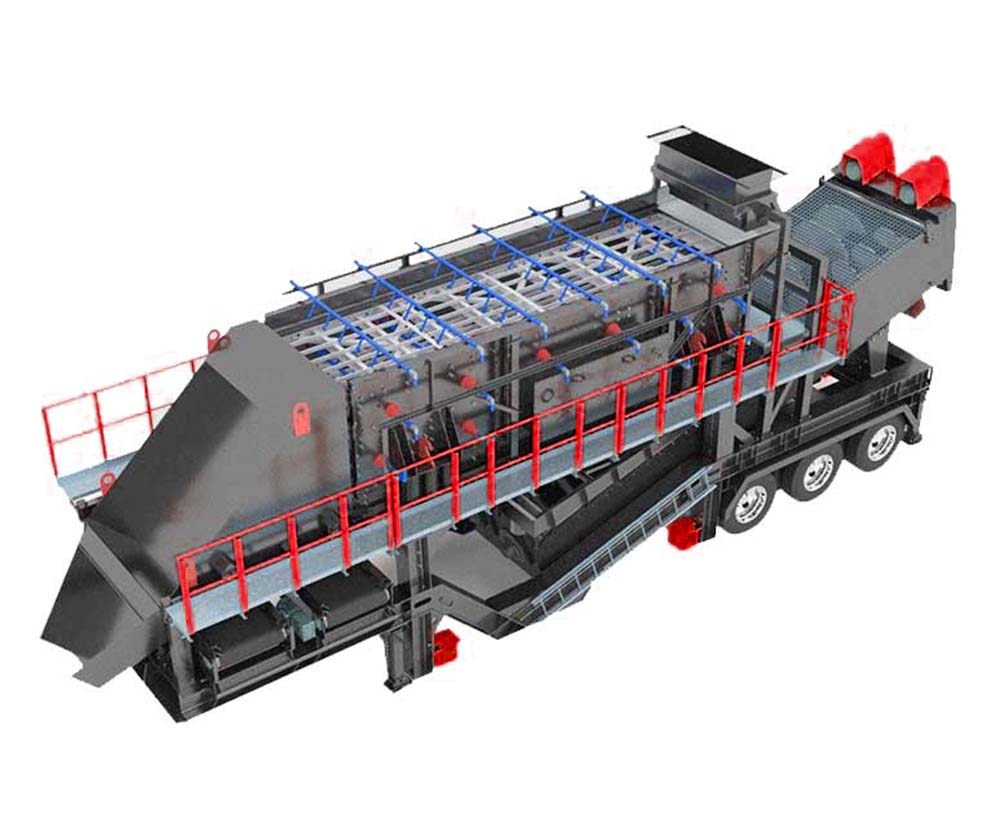

CHASSIS

- BEAM MAINFRAME

- TRIPLE AXLE

- AIR BRAKES | SPRING EMERGENCY BRAKES

- TWELVE 295/R22.5 TIRES (GOODYEAR OR SIMILAR)

- TWO MANUAL LANDING JACKS

- LADDER AND WALKWAY

MORE FEATURES

- Blending Gates included

- Fold down collections box for screen during transport

- 1/4″ AR400 liners standard for feedbox

- Wire mesh screen cloth (upgradable to poly media)

- 2 24 inch wide cross conveyors

- Urethane standard on washer flights

- NI Hard available upon request (Urethane utilized to minimize plant transport weight)

- Outboard bolt-on bearing for washer

- True triple-shaft mine duty horizontal screen

CORPORATE HEADQUARTERS

150 Isidor Ct. Suite 103

Sparks, Nevada 89441

USA

SALES

Sparks, NV

+1 775-686-6900

DISTRIBUTION CENTER

Sparks, NV

ENGINEERING DIVISION

Maddison, WI

DEALER RELATIONS

Seattle, WA

SERVICE DIVISION

Billings, MT

SALES DEPARTMENT

Office: 775-686-6900

sales@aggretek.com

LOGISTICS

logistics@aggretek.com

Office: 775-686-6900 ext. 125

PARTS DEPARTMENT

parts@aggretek.com

Office: 775-686-6900 ext. 128

SERVICE DEPARTMENT

service@aggretek.com

Office: 775-686-6900

DEALER DEVELOPMENT

dealers@aggretek.com

Office: +1 775-686-6900