GO ALMOST ANYWHERE

CRUSH ALMOST ANYTHING

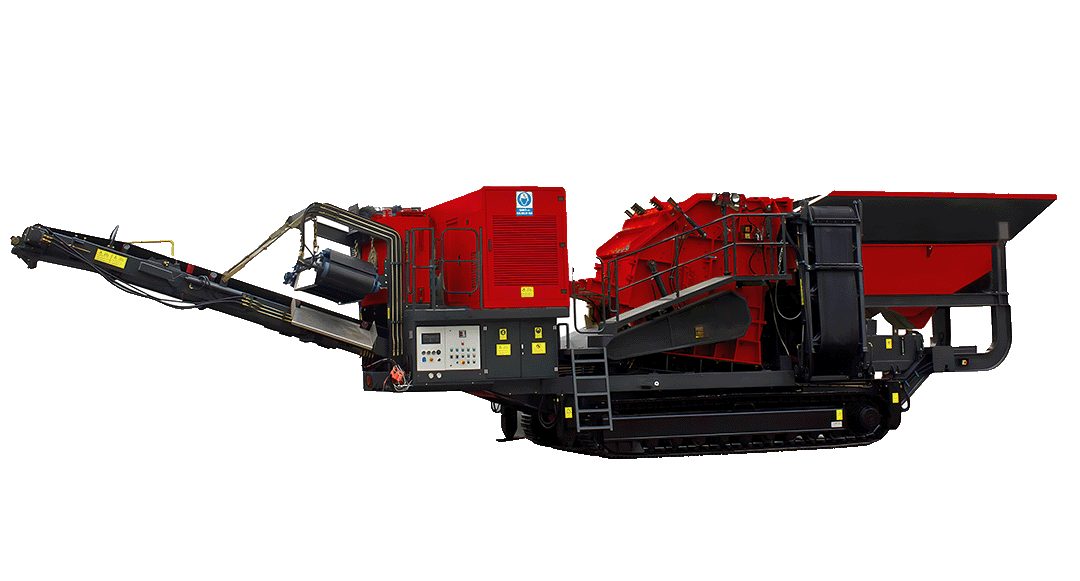

ABOUT AGGRETEK’S WORK HORSE SERIES IMPACTORS

Our Work Horse Series Impact Crushers are powerful machines used in the construction, mining, and recycling industries to crush and process a variety of materials. These crushers are designed to deliver high performance and efficiency while being mobile and easily transportable on tracks or crawler systems.

The primary function of our track-mounted impact crushers is to reduce the size of large rocks, concrete, asphalt, and other materials by utilizing the impact force. They operate by feeding the material into a chamber or rotor where it is struck by hammers or blow bars, resulting in the fragmentation of the material into smaller pieces.

- Mobile units are manufactured with crawler

- Optional screening unit with return belt for Closed Circuit Operation.

- High mobility at operation and at site makes mobile units more practical and handy

- Track-mounted mobile units are driven by diesel engine and hydraulic motors)

- Track-mounted mobile units can be operated by remote control

- Mobile crawler and axle units are manufactured in accordance with road clearance size.

- Low investment cost compared to international competitors.

19 mm (3/4″) steel reinfored rip stop belt

Permanent magnetic separator

Optimized geometry in the crusher box with adjustable swing beams

Hardox hoppers. Feeding with loaders is possible.

Hydraulically foldable side conveyor

Hydraulically vibrating hooper

Large distance between crusher beld (required for recycling)

Folding main conveyor

Tier 4 Final diesel power plant

Crusher

Type

AWHI 3338c

AWHI 3341c

AWHI 3350c

AWHI 3650c

AWHI 3341r

AWHI 3350r

AWHI 3338r

AWHI 3650r

AWHI 3350p

AWHI 3338p

AWHI 3650p

Engine

HP

AWHI 3338c

AWHI 3341c

AWHI 3350c

AWHI 3650c

AWHI 3341r

AWHI 3350r

AWHI 3338r

AWHI 3650r

AWHI 3350p

AWHI 3338p

AWHI 3650p

Engine

kW

AWHI 3338c

AWHI 3341c

AWHI 3350c

AWHI 3650c

AWHI 3341r

AWHI 3350r

AWHI 3338r

AWHI 3650r

AWHI 3350p

AWHI 3338p

AWHI 3650p

Feed Opening

inches

AWHI 3338c

AWHI 3341c

AWHI 3350c

AWHI 3650c

AWHI 3341r

AWHI 3350r

AWHI 3338r

AWHI 3650r

AWHI 3350p

AWHI 3338p

AWHI 3650p

Feed Opening

mm

AWHI 3338c

AWHI 3341c

AWHI 3350c

AWHI 3650c

AWHI 3341r

AWHI 3350r

AWHI 3338r

AWHI 3650r

AWHI 3350p

AWHI 3338p

AWHI 3650p

Feed Size

inches

AWHI 3338c

AWHI 3341c

AWHI 3350c

AWHI 3650c

AWHI 3341r

AWHI 3350r

AWHI 3338r

AWHI 3650r

AWHI 3350p

AWHI 3338p

AWHI 3650p

Feed Size

mm

AWHI 3338c

AWHI 3341c

AWHI 3350c

AWHI 3650c

AWHI 3341r

AWHI 3350r

AWHI 3338r

AWHI 3650r

AWHI 3350p

AWHI 3338p

AWHI 3650p

Capacity

th

AWHI 3338c

AWHI 3341c

AWHI 3350c

AWHI 3650c

AWHI 3341r

AWHI 3350r

AWHI 3338r

AWHI 3650r

AWHI 3350p

AWHI 3338p

AWHI 3650p

REMOTE CONTROLLED

Remote-controlled track machines provide a range of benefits, including improved operator safety, enhanced accessibility, precise control, increased productivity, flexibility, and reduced operator fatigue. These advantages make them valuable tools in industries where efficiency, safety, and performance are paramount.

- Mobility and Versatility: The track-mounted design allows these crushers to move easily and navigate various terrains, including rough or uneven surfaces. They can be transported between job sites without the need for disassembly, making them highly versatile and suitable for both primary and secondary crushing applications.

- Efficient Crushing Performance: Track-mounted impact crushers are equipped with powerful rotors and adjustable impact bars or blow bars. This design ensures efficient crushing of materials, delivering high reduction ratios and excellent particle shape. The impact force generated by these crushers enables the production of consistent and high-quality end products.

- Wide Range of Applications: Track-mounted impact crushers are utilized in a variety of applications. They are commonly used in the construction industry for crushing aggregates, including crushed stone, concrete, and asphalt. These crushers are also employed in mining operations to process ores and minerals. Furthermore, they can be used for recycling applications, crushing demolition waste, and producing reusable materials.

- Versatile Configurations: Track-mounted impact crushers come in various configurations to suit different crushing requirements. They can be equipped with screens to produce a final product of specific sizes or used in open-circuit crushing for maximum flexibility. Some models offer additional features such as integrated magnetic separators or water spray systems for dust suppression, enhancing their versatility and adaptability to different operating conditions.

- Enhanced Safety and Control: Track-mounted impact crushers often feature advanced safety and control systems. These systems may include remote control operation, ensuring operator safety and allowing for easy control of the crusher from a distance. Some models also incorporate overload protection mechanisms to prevent damage to the crusher in case of uncrushable materials or excessive feed.

- Environmental Considerations: Track-mounted impact crushers are designed with environmental sustainability in mind. They often feature low emission engines and efficient power systems, reducing fuel consumption and minimizing their carbon footprint. Additionally, these crushers can be equipped with dust suppression systems to minimize dust emissions and create a safer and more environmentally friendly work environment.

CORPORATE HEADQUARTERS

150 Isidor Ct. Suite 103

Sparks, Nevada 89441

USA

SALES

Sparks, NV

+1 775-686-6900

DISTRIBUTION CENTER

Sparks, NV

ENGINEERING DIVISION

Maddison, WI

DEALER RELATIONS

Seattle, WA

SERVICE DIVISION

Billings, MT

SALES DEPARTMENT

Office: 775-686-6900

sales@aggretek.com

LOGISTICS

logistics@aggretek.com

Office: 775-686-6900 ext. 125

PARTS DEPARTMENT

parts@aggretek.com

Office: 775-686-6900 ext. 128

SERVICE DEPARTMENT

service@aggretek.com

Office: 775-686-6900

DEALER DEVELOPMENT

dealers@aggretek.com

Office: +1 775-686-6900