Genesis Series Cone Crusher

AGGRETEK’s line of GENESIS Cone Crushers is the most diverse product line on the market, including a broad range of sizes and features. From aggregates to mining, no matter which model you need, you can be confident that we have engineered it to meet the most common industry concerns to give you better results.

Complete connectivity and optimised control system for high throughput and reduced maintenance

Achieve maximum throughput with the new range of GENESIS cone crushers available in GEN100, GEN200. GEN300 and GEN400 models, specifically-designed for the aggregates industry. With an integrated user-friendly control system, these configurable, safe crushers are suitable for even your toughest applications.

- The combination of hydraulic cushioning and pressurized gas accumulator allows for smooth passage of steel pieces or other uncrushable materials.

- Ultrasonic testing is performed on the internal structures of swinging jaw shafts to detect and prevent hidden defects.

- The heavy-duty and robust design guarantees consistent high performance, even in the most challenging applications.

- Our foundry produces wear parts that offer a longer lifespan, resulting in reduced cost per ton of crushing.

- Simple and quick operations enable easy replacement of mantles.

- An automatic lubrication system is included as a standard accessory.

METRIC

GENESIS 100

Feed Size (mm)

SS (Extra Fine)

SF (Fine)

F (Medium)

C (Coarse)

CC (Extra Coarse)

GENESIS 100

Min Settings (mm)

SS (Extra Fine)

SF (Fine)

F (Medium)

C (Coarse)

CC (Extra Coarse)

GENESIS 100

Motor Power (kW)

SS (Extra Fine)

SF (Fine)

F (Medium)

C (Coarse)

CC (Extra Coarse)

GENESIS 100

Weight (w/o Motor) (kg)

SS (Extra Fine)

SF (Fine)

F (Medium)

C (Coarse)

CC (Extra Coarse)

GENESIS 300

Feed Size (mm)

SS (Extra Fine)

SF (Fine)

F (Medium)

C (Coarse)

CC (Extra Coarse)

GENESIS 300

Min Settings (mm)

SS (Extra Fine)

SF (Fine)

F (Medium)

C (Coarse)

CC (Extra Coarse)

GENESIS 300

Motor Power (kW)

SS (Extra Fine)

SF (Fine)

F (Medium)

C (Coarse)

CC (Extra Coarse)

GENESIS 300

Weight (w/o Motor) (kg)

SS (Extra Fine)

SF (Fine)

F (Medium)

C (Coarse)

CC (Extra Coarse)

GENESIS 200

Feed Size (mm)

SS (Extra Fine)

SF (Fine)

F (Medium)

C (Coarse)

CC (Extra Coarse)

GENESIS 200

Min Settings (mm)

SS (Extra Fine)

SF (Fine)

F (Medium)

C (Coarse)

CC (Extra Coarse)

GENESIS 200

Motor Power (kW)

SS (Extra Fine)

SF (Fine)

F (Medium)

C (Coarse)

CC (Extra Coarse)

GENESIS 200

Weight (w/o Motor) (kg)

SS (Extra Fine)

SF (Fine)

F (Medium)

C (Coarse)

CC (Extra Coarse)

GENESIS 400

Feed Size (mm)

SS (Extra Fine)

SF (Fine)

F (Medium)

C (Coarse)

CC (Extra Coarse)

GENESIS 400

Min Settings (mm)

SS (Extra Fine)

SF (Fine)

F (Medium)

C (Coarse)

CC (Extra Coarse)

GENESIS 400

Motor Power (kW)

SS (Extra Fine)

SF (Fine)

F (Medium)

C (Coarse)

CC (Extra Coarse)

GENESIS 400

Weight (w/o Motor) (kg)

SS (Extra Fine)

SF (Fine)

F (Medium)

C (Coarse)

CC (Extra Coarse)

Capacity (t/h)

Setting 6 (mm)

GEN100

GEN300

GEN300

GEN400

Capacity (t/h)

Setting 8 (mm)

GEN100

GEN300

GEN300

GEN400

Capacity (t/h)

Setting 10 (mm)

GEN100

GEN300

GEN300

GEN400

Capacity (t/h)

Setting 13 (mm)

GEN100

GEN300

GEN300

GEN400

Capacity (t/h)

Setting 16 (mm)

GEN100

GEN300

GEN300

GEN400

Capacity (t/h)

Setting 19 (mm)

GEN100

GEN300

GEN300

GEN400

Capacity (t/h)

Setting 22 (mm)

GEN100

GEN300

GEN300

GEN400

Capacity (t/h)

Setting 25 (mm)

GEN100

GEN300

GEN300

GEN400

Capacity (t/h)

Setting 32 (mm)

GEN100

GEN300

GEN300

GEN400

Capacity (t/h)

Setting 38 (mm)

GEN100

GEN300

GEN300

GEN400

Capacity (t/h)

Setting 45 (mm)

GEN100

GEN300

GEN300

GEN400

Capacity (t/h)

Setting 51 (mm)

GEN100

GEN300

GEN300

GEN400

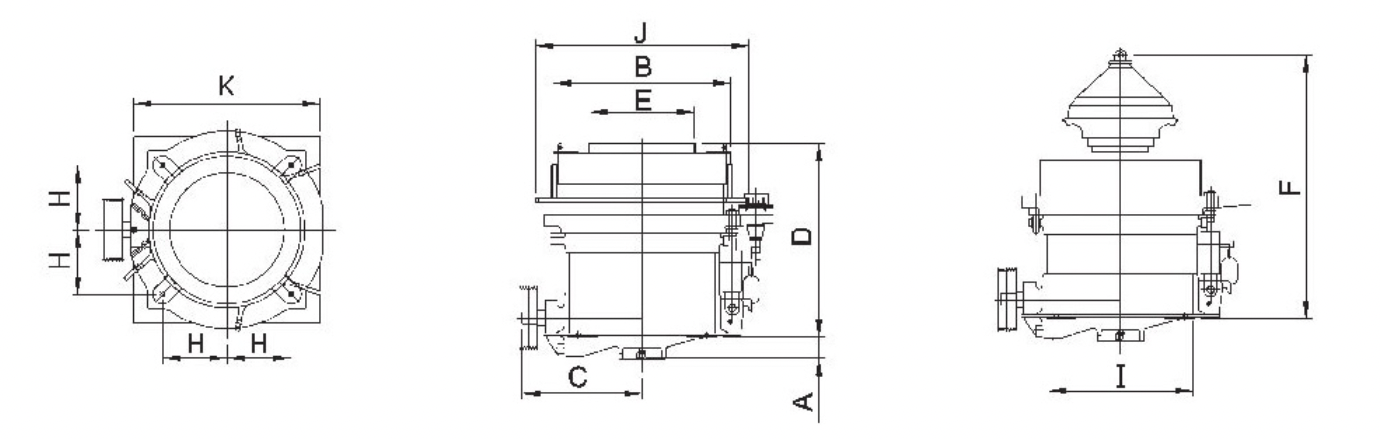

Dimensions (mm)

A

GEN100

GEN300

GEN300

GEN400

Dimensions (mm)

B

GEN100

GEN300

GEN300

GEN400

Dimensions (mm)

C

GEN100

GEN300

GEN300

GEN400

Dimensions (mm)

D

GEN100

GEN300

GEN300

GEN400

Dimensions (mm)

E

GEN100

GEN300

GEN300

GEN400

Dimensions (mm)

F

GEN100

GEN300

GEN300

GEN400

Dimensions (mm)

G

GEN100

GEN300

GEN300

GEN400

Dimensions (mm)

H

GEN100

GEN300

GEN300

GEN400

Dimensions (mm)

I

GEN100

GEN300

GEN300

GEN400

Dimensions (mm)

J

GEN100

GEN300

GEN300

GEN400

CORPORATE HEADQUARTERS

150 Isidor Ct. Suite 103

Sparks, Nevada 89441

USA

SALES

Sparks, NV

+1 775-686-6900

DISTRIBUTION CENTER

Sparks, NV

ENGINEERING DIVISION

Maddison, WI

DEALER RELATIONS

Seattle, WA

SERVICE DIVISION

Billings, MT

SALES DEPARTMENT

Office: 775-686-6900

sales@aggretek.com

LOGISTICS

logistics@aggretek.com

Office: 775-686-6900 ext. 125

PARTS DEPARTMENT

parts@aggretek.com

Office: 775-686-6900 ext. 128

SERVICE DEPARTMENT

service@aggretek.com

Office: 775-686-6900

DEALER DEVELOPMENT

dealers@aggretek.com

Office: +1 775-686-6900